top of page

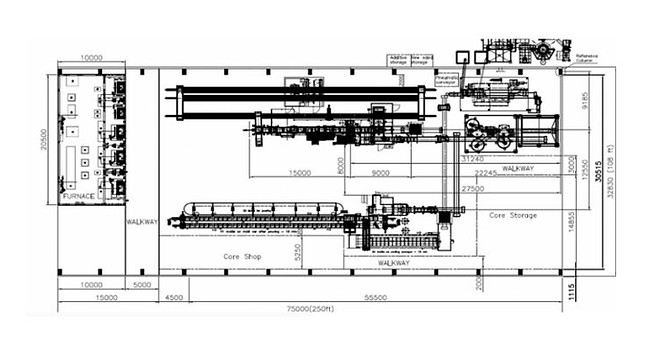

Infrastructure : Our Plant

Factory Land = 13 Acres

Electricity = Express feeder

Gen-set Back up = 750 KVA

Connected Load = 3500 KVA

Covered Area = 80,000 Sq. (approx.)

Premises adhere to worldwide standards

Moulding Lines

%20-1_edited.jpg)

Sinto FBO III (N)

(Sintokogio, Japan) (Flask-less)

Specifications:

Box Size= 660x508x130-200/130-200 Moulds= 90-133/hr

HWS HSP-2D

(HWS, Germany) (Flask Mould)

Specifications:

Box Size= 800x650x250/250-300

Moulds= 35-45/hr

Melt Shops

Electrotherm Induction Furnaces with leading IGBT technology

1 ton Tri-Track / 2750 KW & 500 Kg / 550 KW

Total Melting Capacity of 5.50 Tons / hour (3200 tons/Month)

Pouring Ladles for CI and SG Iron

Vibratory Charge Station along with various cranes.

Electronite Datacast Entouch for precise details of every charge.

Sand Plant

.jpg)

Durmeier, Germany and

Simpson Technologies, USA

Capacity = 50 Tons/hour

No Spillage Conveyors

Along with Dust Collection System

Sand multi cooler with a capacity of 60 tons/hour

Core Shooters

Fettling Shop

Cold box and shell core shooters

Horizontal Parting

Vertical Parting

Shot Blast Machine

Hanger Type & Tumblast

Make = Gostol, Slovenia

Capacity= 3 tons/ Hr each

Various Double Bench Sanders and Grinders

Machine Shop

The machine shop has a variety of CNC machines, including Cincinnati VMCs and Chiron 4 and 5-axis machines.

Various lathes and turning centres

Machine shop including various machine center

bottom of page